ALBATROSS BOARD FAQ

ALBATROSS BOARD (FAQ)

Q1. Why call it “ALBATROSS BOARD”?

The characteristics of this product: white and ultra lightweight, high endurance, flat and smooth like a flying Albatross.

Q2. What is the core material?

Foamed Polyethylene resin, 100 % pure resin – High Density Polyethylene and Low Density Polyethylene mixed.

Q3. Can it be used New Zealand UV Weather conditions?

4 years Weather-ability test at Beach side (300m from ocean) 4-year weather-availability tested with no problems at all.

Q4. How to cut ALBATROSS BOARD by a panel saw and/or running saw?

Since a panel saw and running saw are circular saws, cutting is archived by the feeding speed rather than the saw blade’s rotation speed. Please implement work after confirming the feeding speed and rotation number of the saw. A Carbide chip saw is the most suitable edge cutting tool.

Q5. How to bend ALBATROSS BOARD?

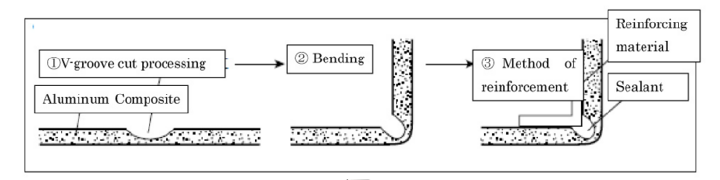

There is a limit to bending processing using a general press brake for Aluminum Composite panels. If bending of a smaller R is necessary, the V-groove processing method may be used.

(Special bending process)

-

V-groove cut processing

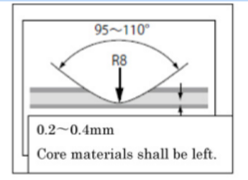

V-groove cut processing can be made by fitting a V-groove blade to a NC router, electric trimmer, or circular saw. V-groove cut processing shall be made with the bottom of the groove left with a 0.2mm – 0.4mm resin portion of the core material.

-

Bending processing

Bend evenly in order not to cut the aluminum sheet of the surface proceed with the V-groove cut.

-

Method of reinforcement

Since the bending portion does not have its original strength, reinforce the groove side of bent portion with a reinforcing material, such as an aluminum angle attachment with a bonding agent. According to necessity, the inside of V-groove shall be filled with a sealant.